- Aberdeen Oil Works

- Addiewell Oil Works

- Almondhill Oil Works

- Annick Lodge Oil Works

- Arden Oil Works

- Armadale Oil Works

- Auchenheath Oil Works

- Avonhead Oil Works

- Balgray Oil Works

- Ballat Oil Works

- Bathgate Oil Works

- Bathville Oil Works

- Bellsdyke Oil Works

- Bellsquarry Oil Works

- Benhar Oil Works

- Binnend Oil Works

- Birkenshaw Oil Works

- Bishop Street Oil Works

- Blackburn Oil Works

- Blackstone Oil Works

- Blackstoun Oil Works

- Blochairn Oil Works

- Boghall Oil Works

- Bredisholm Oil Works

- Breich Oil Works

- British Asphalte Oil Works

- Broxburn Oil Works

- Broxburn - Bell's Stewartfield Oil Works

- Broxburn - Albyn Oil Works

- Broxburn - East Mains Oil Works

- Broxburn - Greendykes Oil Works

- Broxburn - Hallfarm Oil Works

- Broxburn - Hutchinson's Oil Works

- Broxburn - Poynter's Oil Works

- Broxburn - Steele's Oil Works

- Broxburn - Steele's Stewartfield Oil Works

- Buckside Oil Works

- Burngrange Oil Works

- Calderbank Oil Works

- Canalbank Oil Works

- Champfleurie Oil Works

- Clippens Oil Works

- Cobbinshaw North Oil Works

- Cobbinshaw South Oil Works

- Coneypark Oil Works

- Craigie Oil Works

- Crown Point Oil Works

- Dalmeny Oil Works

- Deans Oil Works

- Doura Oil Works

- Drumbow Oil Works

- Drumcross Oil Works

- Drumgray Oil Works

- Dryflat Oil Works

- East Fulton Oil Works

- East Hermand Oil Works

- Eldin Oil Works

- Falkirk Oil Works

- Fergushill Oil Works

- Forthbank Oil Works

- Forth & Clyde Oil Works

- Gavieside Oil Works

- Grange Oil Works

- Grangepans Oil Works

- Greengairs Oil Works

- Hareshaw Oil Works

- Hartwood Oil Works

- Hawick Oil Works

- Hermand Oil Works (1866)

- Hermand Oil Works (1883)

- Holmes Oil Works

- Hopetoun Oil Works

- Hurlford Oil Works

- Inkerman Oil Works

- Inverkeithing Oil Works

- Kilrenny Oil Works

- Kilwinning Oil Works

- Kirkmuirhill Oil Works

- Kirkwood Oil Works

- Lanark Oil Works

- Lanemark Oil Works

- Levenseat Oil Works

- Limerigg Oil Works

- Linwood Oil Works

- Loanhead Oil Works

- Lochburn Road Oil Works

- Lochgelly Oil Works

- Longrigg Oil Works

- Magdalene Oil Works

- Methil Oil Works

- Millburn Oil Works

- Nettlehole Oil Works

- Niddry Castle Oil Works

- Nitshill Oil Works

- Oakbank Oil Works

- Palacecraig Oil Works

- Pathhead Oil Works

- Patterton Oil Works

- Pentland Oil Works

- Philpstoun Oil Works

- Port Dundas Oil Works

- Possil Oil Works

- Pumpherston Oil Works

- Raebog Oil Works

- Riggend Oil Works

- Rochsoles Oil Works

- Rochsolloch Oil Works

- Roman Camp - Almondfield Oil Works

- Roman Camp - Cawburn Oil Works

- Roman Camp Oil Works (1892)

- Roman Camp - Shale Oil Works

- Rosebank Oil Works

- Roughcraig Oil Works

- Rumford Street Oil Works

- Seafield Oil Works

- Shawsburn Oil Works

- Sheepford Locks Oil Works

- Shettleston Oil Works

- Shotts Oil Works

- Stand Oil Works

- Stanrigg Oil Works

- Stonehouse Oil Works

- Straiton Oil Works

- St. Rollox Works

- Swinehill Oil Works

- Tarbrax Oil Works

- Uphall Oil Works

- Uphall - Railway Oil Works

- Uphall - Wyllie's Oil Works

- Vulcan Chemical Works

- Wardend Oil Works

- Wattston Oil Works

- Westfield & Capeldrae Oil Works

- Westwood Oil Works (1941)

- Westwood Oil Works (1866)

- Whitebog Oil Works

- Whitehill Oil Works (Lanarkshire)

- Whitehill Oil Works (Midlothian)

- Whiterigg Oil Works

- Woodhall Oil Works

Wardend Oil Works

The history of this small oil works remains unclear. One report records that the cannel coal found at Wardend colliery was first used for oil production "about ten years prior to outbreak of war" (i.e. c.1904); another source stated that oil works were being constructed when war broke out, were then discontinued, but were "renewed in 1919 by means of a process which involves the use of superheated steam".

It appears therefore than Wardend pit, and perhaps an associated oil works, were taken over by the North Ayrshire Coal and Oil Co. Ltd., a company formed in 1916 and registered in England (142755), that constructed retorts designed by Robert Maclaurin. The works may have served as a pilot plant for the development of Maclaurin's process to manufacture smokeless fuels. A trial plant equipped with Maclaurin retorts were installed at Glasgow Corporation's Dalmarnock gas works in about 1923, which produced a solid smokeless fuel, gas and a crude oil.

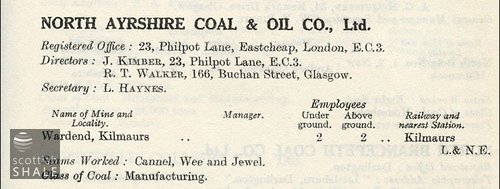

Mining operations at Wardend appear to have been on a small scale (in 1924 they are recorded as employing only four staff) , and the North Ayrshire Coal and Oil Co. Ltd was wound-up in 1926. The lease of Wardend colliery was acquired by the Franco-British oil trust, in 1930 but there is no evidence that mining activity was resumed.

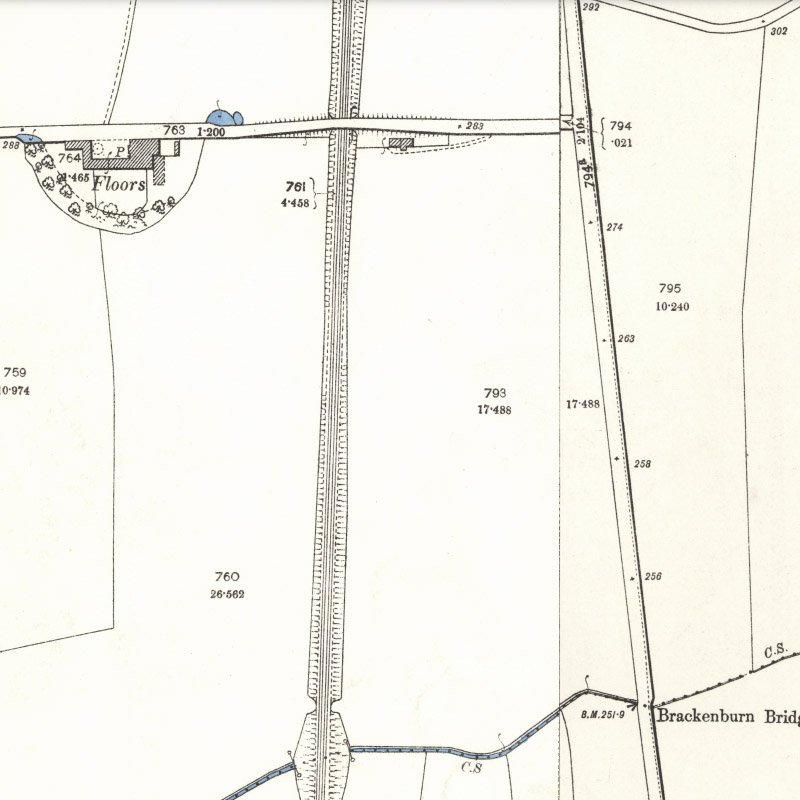

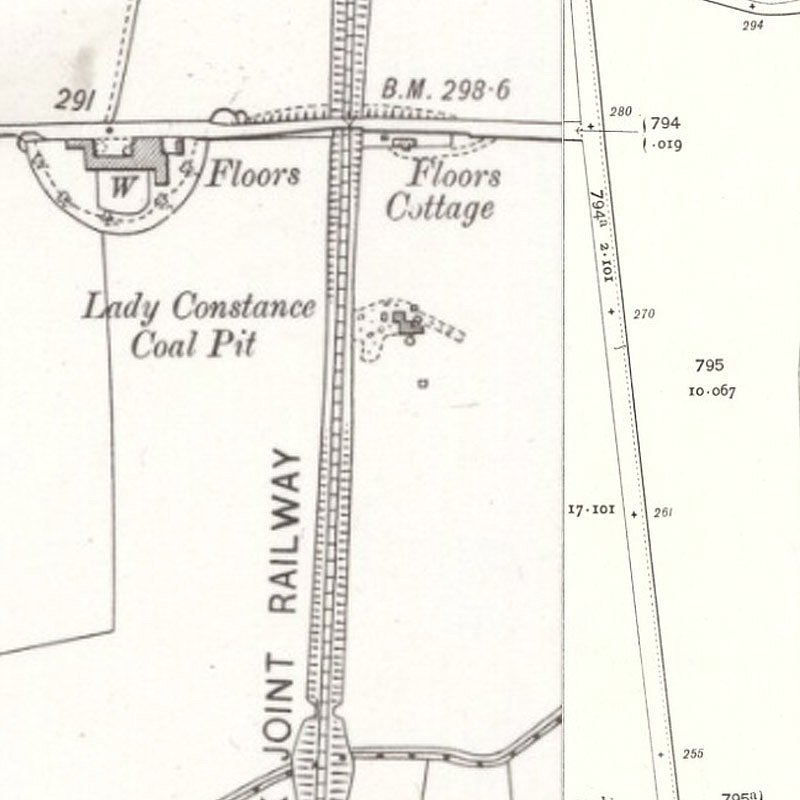

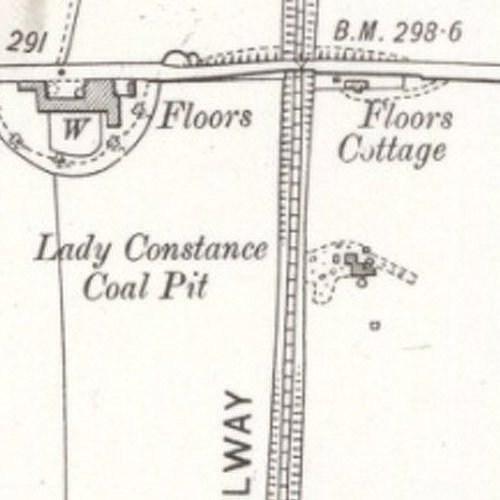

It seems probable that the oil works were closely associated with Wardend colliery, and that this was at a site beside the Glasgow and Kilmarnock Joint railway, immedately north of Kilmaurs, marked on the OS map of 1911 (surveyed 1908) as "Lady Constance pit". The pit, presumably named in honour of local landowner Lady Sofia Constance Montgomery, does not appear on 1897 edition of the map.

Above left: From The Colliery Year Book and Coal Trades Directory, 1924.

Drawings & Plans

Maclaurin smokeless fuel plant at Dalmarnock gas works, Glasgow, c.1923

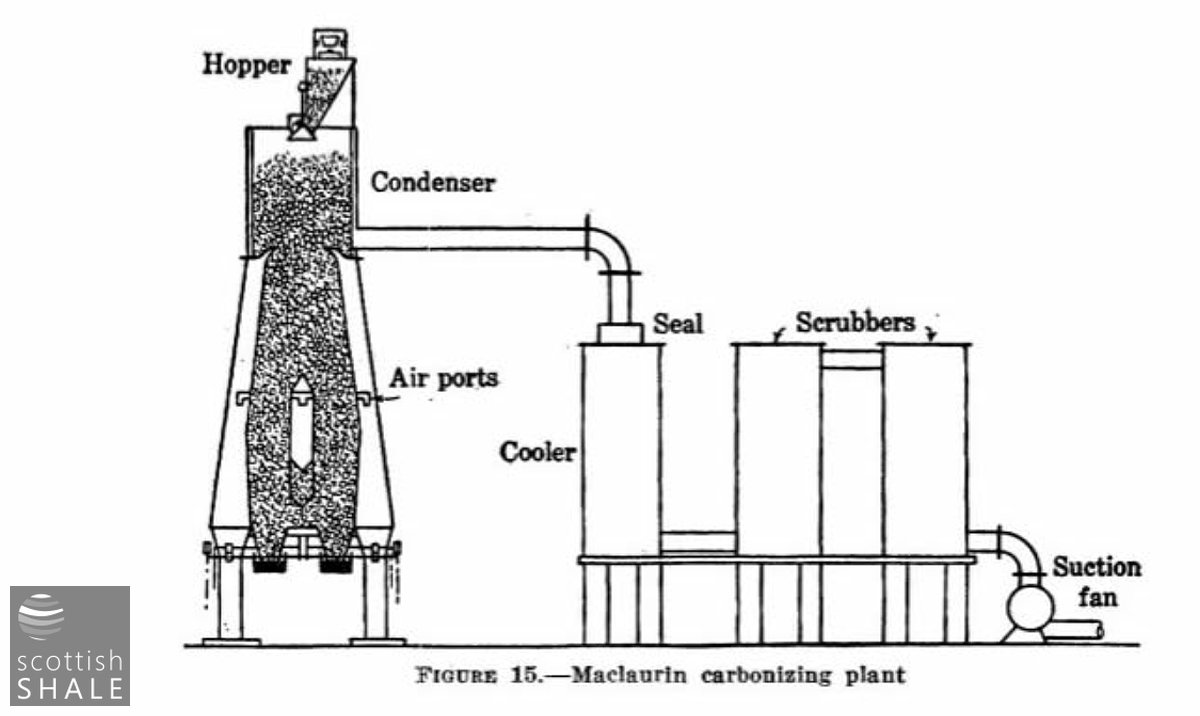

Drawing of the Maclaurin retort at Dalmarnock gas works

Recent images

View looking south from the railway bridge close to Floors Farm. The rough ground, centre left, used for stocking spent animal bedding, is the site of Lady Constance pit, and presumably also that of Wardend oil works. April 2016.

A cannel-coal of Wardend Colliery, near Kilmaurs, yields from 39 to 53.7 gallons of crude oil per ton. Oil-works for its distillation were being erected when the war broke out.

Summary of the progress of the Geological Survey, 1919

.......

At present only one seam containing cannel is being worked in this part of the county. This is at Wardend (formerly Wheatrigg) Colliery, near Kilmaurs, where the seam is known as the Gas or Cannel Coal.... The seam is of interest as the only one which there is any attempt to use for the distillation of oil for some 10 years prior to the outbreak of war. Distillation had been temporarily discontinued, but was renewed in 1919 by means of a process which involves the use of superheated steam. Tests by different methods give from 39 to 72 gallons of crude oil per ton, with from 32 to 111 lbs. of sulphate of ammonia.

Memoirs of the Geological Survey in Scotland Vol XXIV Cannel Coals, Lignite and Mineral Oil in Scotland by W. Gibson, 1922

.......

The NORTH AYRSHIRE COAL & OIL COMPANY Limited.

At an Extraordinary General Meeting of the Members of the above named Company, duly convened, and held at 23, Philpot-lane, in the city of London, on the 27th day of October, 1926, the following Extraordinary Resolution was duly passed:- " That it has been proved to the satisfaction of this Meeting that the Company cannot, by reason of its liabilities, continue its business, and that it is advisable to wind up the same, and accordingly that the Company be wound up voluntarily; and that Mr. Maitland Chater, of 74, Cheapside, in the city of London, be appointed Liquidator for the purposes of such winding-up." JOSEPH KIMBER, Chairman.

London Gazette, 5th November 1926

.......

Another Ayrshire enterprise which survived until 1914 was that Wardend Colliery, near Kilmaurs, a cannel from a seam in the Limestone Group furnishing the retorting material. The operations here were under the direction of Mr. R. Maclaurin and were his initial attempt at oil production on a commercial scale.

Mining Engineer, Vol 81. 1931

.......

FRANCO-BRITISH OIL TRUST

Report for 1930 states that the company has acquired lease of Wardend Colliery which contains cannel coal of good analysis. Owing to considerable delay on behalf of contractors and others, the first unit of plant erected at Belvedere, Kent, by Patent Coal Carbonisation Trust has only recently come into operation.

Chemical Age, Vol 24, 1931

.......

A former villager of Bothwell, Mr Robert Maclaurin. third son of the late Mr John P. Laurin. has obtained the approval of the Gas Committee of Glasgow Corporation to an experimental manufacture of smokeless fuel by a process invented by him. MacLaurin is chemist by profession, and has been working at the problem for some time.

Hamilton Advertiser, 13th June 1914

.......

SMOKELESS FUEL EXPERIMENTS.

Glasgow's Pioneer Step. Gas Committee's Plan Adopted. 71 votes to 12 Glasgow Corporation this afternoon decided to inaugurate experiments in the production of smokeless fuel. The recommendation of the Gas Committee was that the general manager be instructed to experiment at Provan Gasworks with a Woodall-Duckham. plant for the production of smokeless fuel; that a 5-unit battery of Maclaurin producers be installed at Dalmarnock Gasworks for the manufacture of smokeless fuel and for supplying Dalmarnock electricity station with industrial gas.

Dundee Evening Telegraph, 20th September 1923

.......

A SMOKELESS GLASGOW.

Age-Long Dream Coming True.

A few years a smokeless Glasgow will be an accomplished fact, and when Glasgow throws off its thrall soot and grime the age-old dream of the hygienists will come true. The pioneers in this great campaign for health and brightness prophesy this with confidence. They have facts and figures to support them. The Maclaurin process of smokeless fuel, after years of experiment, is nearing perfection. In practice it has proved what the sceptics would never believe, that it is economically possible to produce smokeless fuel which can be adopted for ordinary us at ordinary price. In short, the Maclaurin experiments, after twelve years endless research, have justified themselves Mr Maclaurin, the inventor of the process, who personally supervises Glasgow's experimental plant at Dalmarnock Gasworks, has proved that it is possible to put smokeless fuel on the market at the price of good class domestic coal. There is every prospect that further experiments with the bye-products will reduce that estimate.

No More Stoking.

The fact remains, however, that, industrial consideration, the fuel is economically impossible. It is much too expensive for firing boilers or for smelting. It is in making provision for this that the process triumphs. Although the fuel is too expensive the process produces a gas which is surprisingly inexpensive and, although deficient by half in the heating qualities of ordinary gas, it can be produced at a price which will make it possible to replace the present system of stoking by gas heating, and it will be quite cheap, if not cheaper. The gas heating will obviate all the disadvantages of stoking and, what is greater service to the community, rid the air of smoke pollution. It is not proposed to send this gas through the ordinary pipe system, but to supply it to the works by special mains. But the hidden virtues of the process are not yet exhausted. There are still the invaluable bye-products which are released from the coal and are condensed into crude oils, the mysteries of which are still being explored by the chemists. The oil in its crude state is valuable for fuel purposes or for creosoting. The experiments, so far they have gone, have obtained resin, fine lubricating oils, colours, and disinfectants. They have revealed pigments of blue-black and brown colour and dyes, particularly of the green series. There is also the usual deposit of sulphate of ammonia for fertilising purposes, but its commercial value is so low that it is of little consequence. It is shown that out of every ton of coal eleven hundredweight of carbonised fuel can be obtained, about 25,000 cubic feet of gas, and from 15 to 17 gallons of crude oil. The carbonised fuel can be supplied at 42s a ton, which is the present cost of good-class household coal. Not only that, but recovers the valuable bye-products, of which there is a criminal waste in the burning of ordinary coal.

Benefit to the Housewife.

There is no doubt that the housewife to get the better of the bargain in exchanging the ordinary coal for carbonised coal. In an independent test it was proved that the fuel radiated consistent heat throughout the room, while big percentage of the heat from ordinary coal never escaped into the room at all. During the test, in which equal quantities of fuel were used, the smokeless fuel burned seven hours, as compared with four and a half hours in the case of coal. There was not much difference in the quantity of ashes. The housewife need have no apprehension about using the fuel. It is easily kindled, although a different method of building it is required. - Instead of layer of paper, a layer of sticks and a layer of coal, the sticks should be built camp-fire fashion in the centre of the grate, and the lumps of fuel grouped round about it. It will kindle readily, and burn with red glow a blue, smokeless flame. The Glasgow Corporation have shown the way in what is likely to prove an inestimable boon to industrial centres. Public health authorities are enthusiastic about it, and prophesy a tremendous improvement in the mortality census and in the health of the city dwellers. The Glasgow pioneers, led by the enthusiastic smoke-fighter, Councillor W. B. Smith, have proved their point in face of violent opposition. They sponsored the cause of Mr Maclaurin twelve years ago, and when in 1923 Mr Maclaurin reported the efficiency of his process, they installed range of five producers at Dalmarnock. This plant is capable of carbonising one hundred tons of coal per day, yielding fifty-five tons of fuel, 1600 gallons of oil, and 2,500,000 cubic feet of gas. Thus the Maclaurin process has proved that a smokeless city is no longer be only a hygienist ideal, but, if only the public will co-operate, an immediate prospect. It has everything to commend it, even price.

Sunday Post, 21st February 1926

.......

£400,000,000 Gas "Grid" Scotland Linked With Coal- Oil Plant Enthusiast's Scheme for Cheap Power

A £400,000,000 scheme to create a Scottish gas " grid" was described by Mr Robert Maclaurin at a meeting the Scottish National Development Council in Glasgow yesterday. Mr Maclaurin suggested to the new executive committee that they should immediately form a gas and oil development committee to inquire into the possibilities of obtaining oil from British coal. At the moment this country was importing annually 8 1/4 million tons of oil, which was displacing from 12 to 16 million tons of British coal. These oil importations were steadily increasing. Speaking of the benefits of producing oil from home produced coal, he said they could not do it economically unless they obtained an outlet for gas, and he was anxious that the proposed committee should look into the question of developing a gas "grid " for the whole of Scotland. If they got that market, they could make oil at a price of about threepence per gallon, and then electrify the railways on the Diesel system. Cheapest Source Gas was the cheapest source of heat. Electricity was the thing of the future, but electricity could not compete with gas as source of heat. Gas at 4d per therm was cheaper than coal for domestic use. The total cost of supplying gas "grid" in Scotland, including carbonisation plant, estimated to £400,000,000. The scheme would give a much required fillip to the iron and steel industry, and would lead to a smokeless Scotland. Sir James Lithgow replied that they had the same matter before them previously, and the compelling reason for their failure to set up such a committee was that their staff and resources were already fully employed other investigations. Obviously a number of Mr Maclaurin's statements were not just fully accepted, otherwise the scheme would have presumably been going on already, but it was quite appropriate that the executive should consider the matter carefully.

Dundee Courier, 17th April 1933

.......

£10,000 CLAIM AGAINST CIVIC OFFICIAL GLASGOW CORPORATION TO DEFEND ACTION

An action for £10,000 has been raised in the Sheriff Court, Paisley, by Mr Robert MacLaurin against the general manager of the Gas Department of Glasgow Corporation. This is recorded in a minute of the Gas Committee for submission at the Corporation meeting to-morrow. The minute states that the action is " for damages in respect of alleged false and misleading statements contained in reports made by the general manager to this committee in connection with the MacLaurin smokeless fuel plant." The committee heard the general manager in regard to the matter, and after discussion agreed that the action be defended at the expense of the Corporation, and that the Town Clerk be authorised to take the necessary steps- Councillor Hugh Campbell dissenting.

Dundee Courier, 27th October 1937

.......

CHEMIST WAS FUEL EXPERT

Mr Robert Maclaurin, The Homestead, Stirling, died while travelling in a bus in Glasgow last night. He was analytical chemist who invented a plant for the manufacture of smokeless fuel, producing cheap gas and by-products. It was adopted by Glasgow and other corporations. Maclaurin had offers from the Indian Government to engage in similar work there. Recently he was investigating the possibilities of extracting by products from peat.

Dundee Evening Telegraph, 19th August 1948